What Is The Best Tool That Makes Deep Holes Simple To Drill

Drilling a hole in solid materials, usually, a circle, by means of Deep hole drills is known plainly as drilling. Similarly, precise terminology seems warranted for deep-hole drilling. The drill is making or widening a hole far underground; what else could go wrong?

Explain The Process Of Deep Hole Drilling

It is conventionally agreed that a

depth-to-diameter ratio (D:d) higher than 10:1 indicates a deep hole. The

requirement for more precise and straight cannon barrels led to developing deep

hole drilling techniques, which later found use in various sectors.

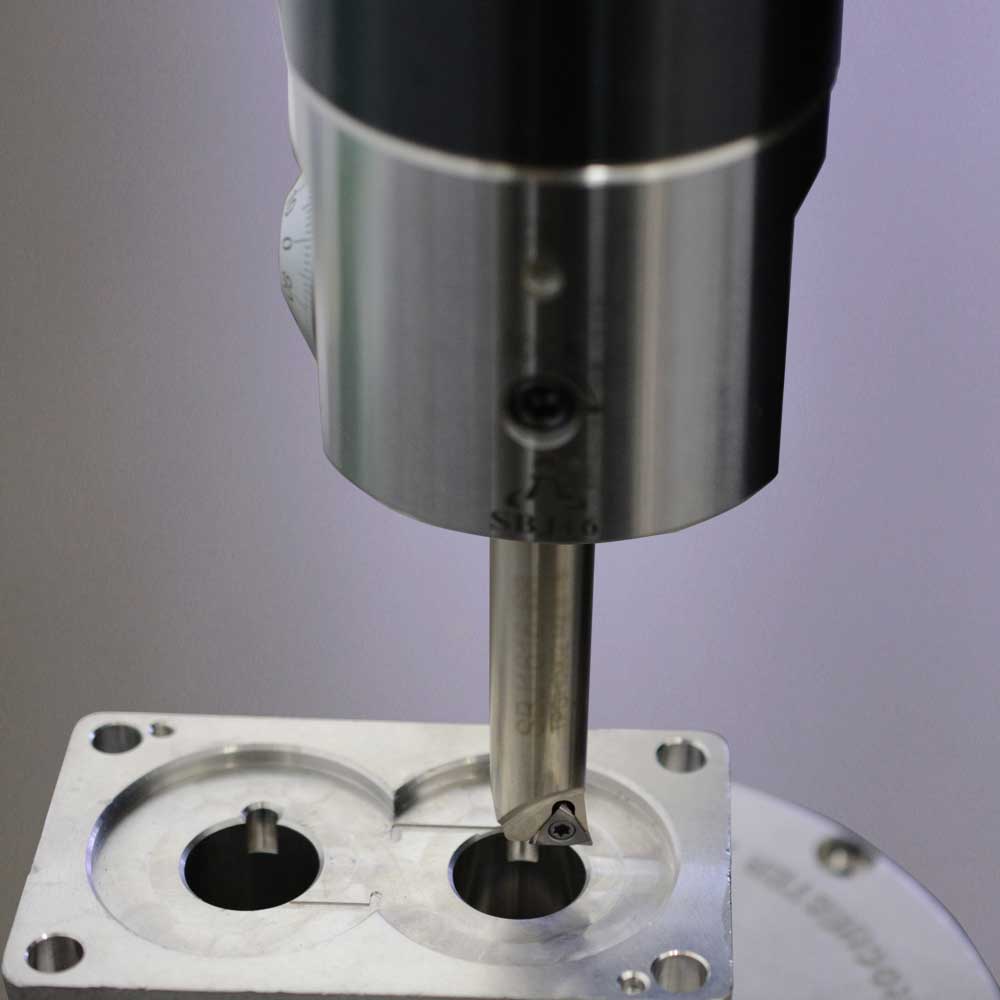

BTA drilling, gun drilling, and other

techniques developed for certain tolerance objectives & typically carried

out on BTA-style deep hole drilling equipment make up the entirety of deep hole

drilling. The use of deep hole drilling allows for precise diameter management,

rightness, and superior surface quality in a wide range of materials, from

aluminium to super-alloys.

Drill a hole in metal with a ratio more

significant than what can be accomplished with a standard numerically

controlled ISO Turning Inserts; deep hole

drilling methods use specialized tools and setups to inject high-pressure

coolant, remove chips cleanly, and then drill to the required depth. In this

way, producers can consistently, precisely, and efficiently meet their

production needs & manufacturing tolerances.

Machines designed for deep hole drilling are

built and put together with accuracy and efficiency. CNC machining centers can

now gun drill up to a certain depth-to-diameter ratio thanks to incorporating

high pressure, through-spindle fluid. With UNISIG, we manufacture BTA & gun

drilling equipment with capabilities well over 400:1 D:d ratios.

Precision Machining Of Deep Holes

Drilling is the first step in the machining

process; however, other operations can be performed to enhance the

concentricity, straightness, surface quality, and inclusion of complicated

features of the deep holes. Most of these procedures can be executed utilizing

standard BTA deep hole drilling tools, and they machine the interior wall of

the hole in much the same way as external machining processes.

Conclusion

Workpieces having pre-existing bores, whether

from drilling or centrifugal casting, are ideal for processing. For example,

the hydraulic cylinder company uses skiving machines, while the landing gear

actuators industry uses bottle boring. Both of these deep hole machining

operations are optimized for their respective fields.

Comments

Post a Comment